Following are some components of the engines -

1. Flywheel

The flywheel is a cast iron, aluminum, or zinc disk that is mounted at one end of the crankshaft to provide inertia for the engine. Inertia is the property of matter by which any physical body persists in its state of rest or uniform motion until acted upon by an external force. During the operation of a reciprocating engine, combustion occurs at distinct intervals. the flywheel supplies the inertia required to prevent loss of engine speed and possible stoppage of crankshaft rotation between combustion intervals.

2. Bearings

The bearing is the component used to reduce friction and to maintain clearance between stationary and rotating components of an engine. Bearings, or bearing surfaces, are located on the crankshaft, connecting rod, and camshaft, and also in the cylinder block. Bearings can be subjected to radial, axial(thrust), or a combination of radial & axial loads. Bearings can be classified as friction or anti-friction bearings.

|

| Bearings & types |

3. Carburetor

This is the Venturi flow device which meters the proper amount of fuel into the airflow using a pressure differential. For many decades it was the basic fuel metering system on all automobile (and other) engines. It is still used on low-cost small engines like lawnmowers but is uncommon on new automobiles.

|

| Carburetor |

4. Catalytic converter

The catalytic converter helps to reduce airborne pollutants that could harm people as well as the environment, turning 90% of harmful emissions into less harmful gasses. A well-maintained catalytic converter improves the efficiency of your vehicle, directly affecting its overall health and performance.

|

| Catalytic Converter |

5. Connecting Rod Bearings

Connecting rod bearings provide the rotating motion of the crankpin within the connecting rod, which transmits cycling loads applied to the piston. Connecting rod bearings are mounted on the Big end of the connecting rod. A bearing consists of two parts.

A starter also known as a self-starter, cranking motor, or starter motor is a device used to rotate (crank) an internal combustion engine to initiate the engine's operation under its own power.

|

| Starter |

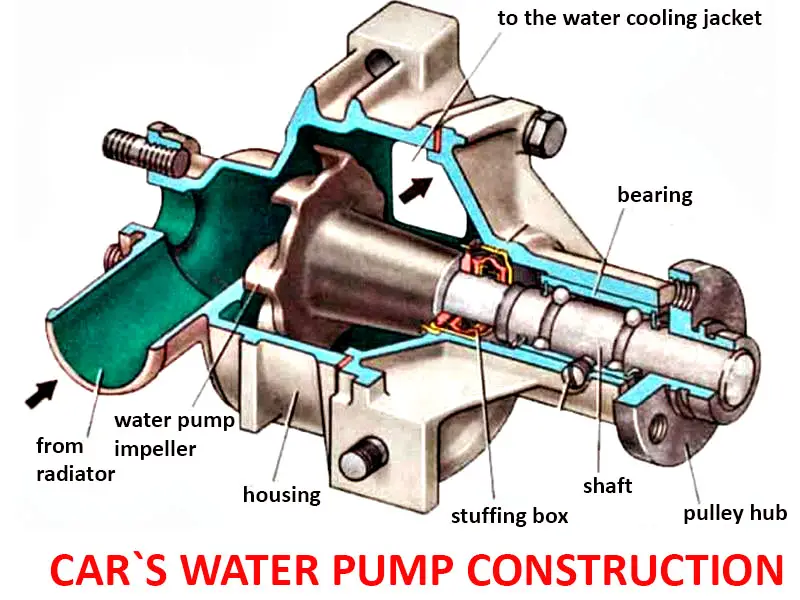

The water pump, also known as the coolant pump, is the heart of the engine's cooling system. It is the water pump's job to regulate the coolant flow rate and to constantly circulate coolant throughout the engine and cooling system.

The supercharger is a general name for an air compressor used to increase the pressure or density of air entering an engine, providing more oxygen with which to burn fuel.

The radiator transfers the heat from the fluid inside to the air outside, thereby cooling the fluid, which in turn cools the engine. Radiators are also often used to cool automatic transmission fluids, air conditioner refrigerant, intake air, and sometimes to cool motor oil or power steering fluid.

Most engines have an engine-driven fan to increase airflow through the radiator and through the engine compartment, which increases waste heat removal from the engine. Fans can be driven mechanically or electrically and can run continuously or be used only when needed.

The fuel pump is located at the fuel tank and is designed to carry the required quantity of fuel from the tank to the engine at the required pressure.

|

| Fuel Pump |

A pressurized nozzle that sprays fuel into the incoming air on SI engines or into the cylinder on CI engines. On SI engines, fuel injectors are located at the intake valve ports on multipoint port injector systems and upstream at the intake manifold inlet on throttle body injector systems. In a few SI engines, injectors spray directly into the combustion chamber.

14. Glow plug

The glow plug is a small electrical resistance heater mounted inside the combustion chamber of many CI engines and is used to preheat the chamber enough so that combustion will occur when first starting a cold engine. The glow plug is turned off after the engine is started.

The gasket serves as a sealant between the engine block and head where they bolt together. They are usually made in a sandwich construction of metal and composite materials. Some engines use liquid head gaskets.

|

| Head gasket |

References:

1. Engineering Fundamentals of IC Engine - Willard W. Pulkrabek

2. http://www.substech.com/dokuwiki/doku.php?id=bearings_in_internal_combustion_engines

3. wikipedia.com

:max_bytes(150000):strip_icc()/Fuelinjector-5c2ce49a46e0fb00014ac030.png)

No comments:

Post a Comment